SVU Enterprises provides complete water purification systems for the pharmaceutical industry. We specialize in designing, building, and maintaining validated systems that produce Purified Water (PW) and Water for Injection (WFI) to strict pharmacopeia standards. Our solutions guarantee compliance, ensure product safety, and protect your manufacturing process from disruption.

Chlorination’s system, Multigrade filters (MGF), Softener units, Ultra filtration system (UF), Pretreatment Units, Reverse Osmosis (RO) Systems, Purified Water (PW), Water for Injection (WFI) Systems and Pure Steam Generator designed to meet stringent industry requirements.

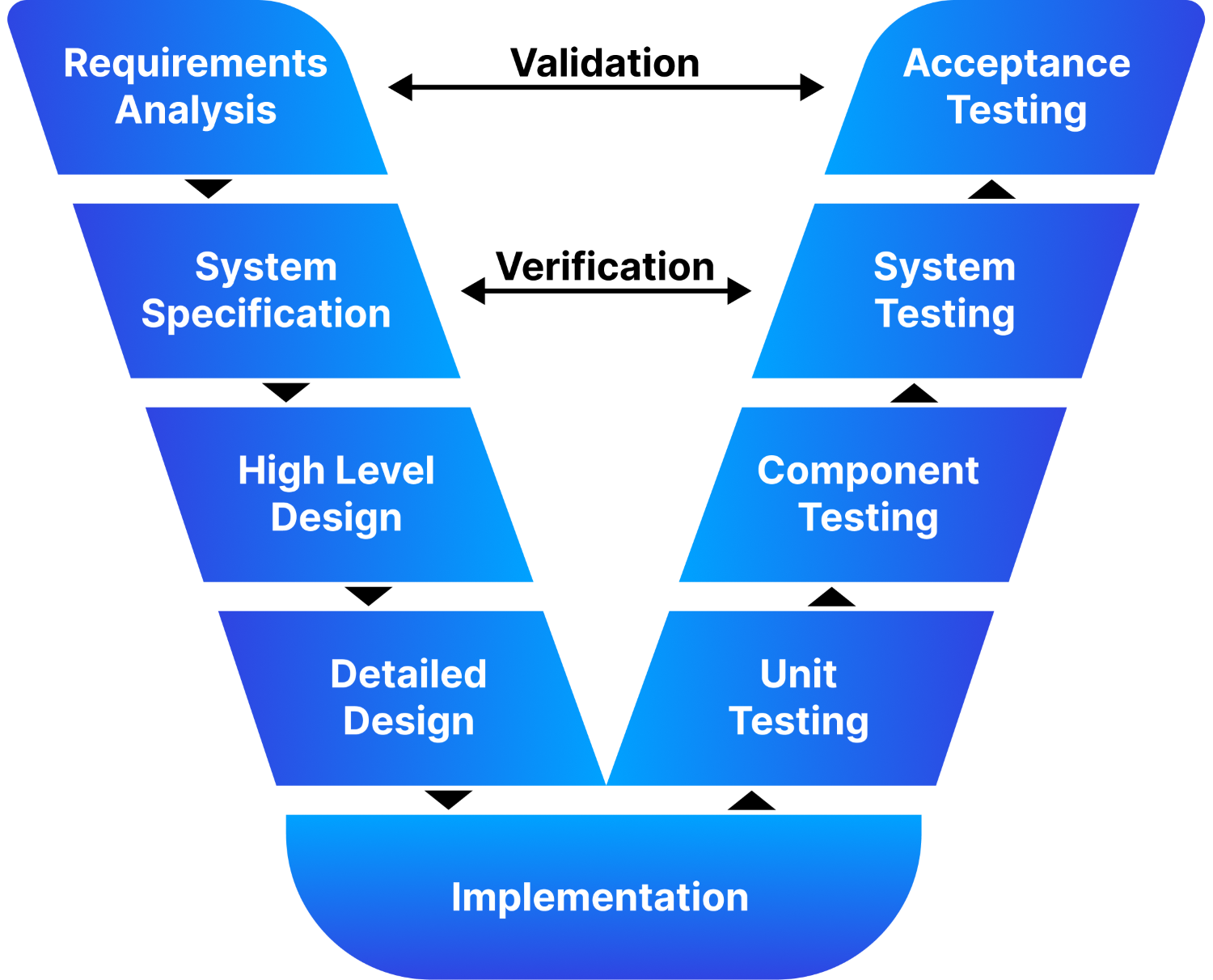

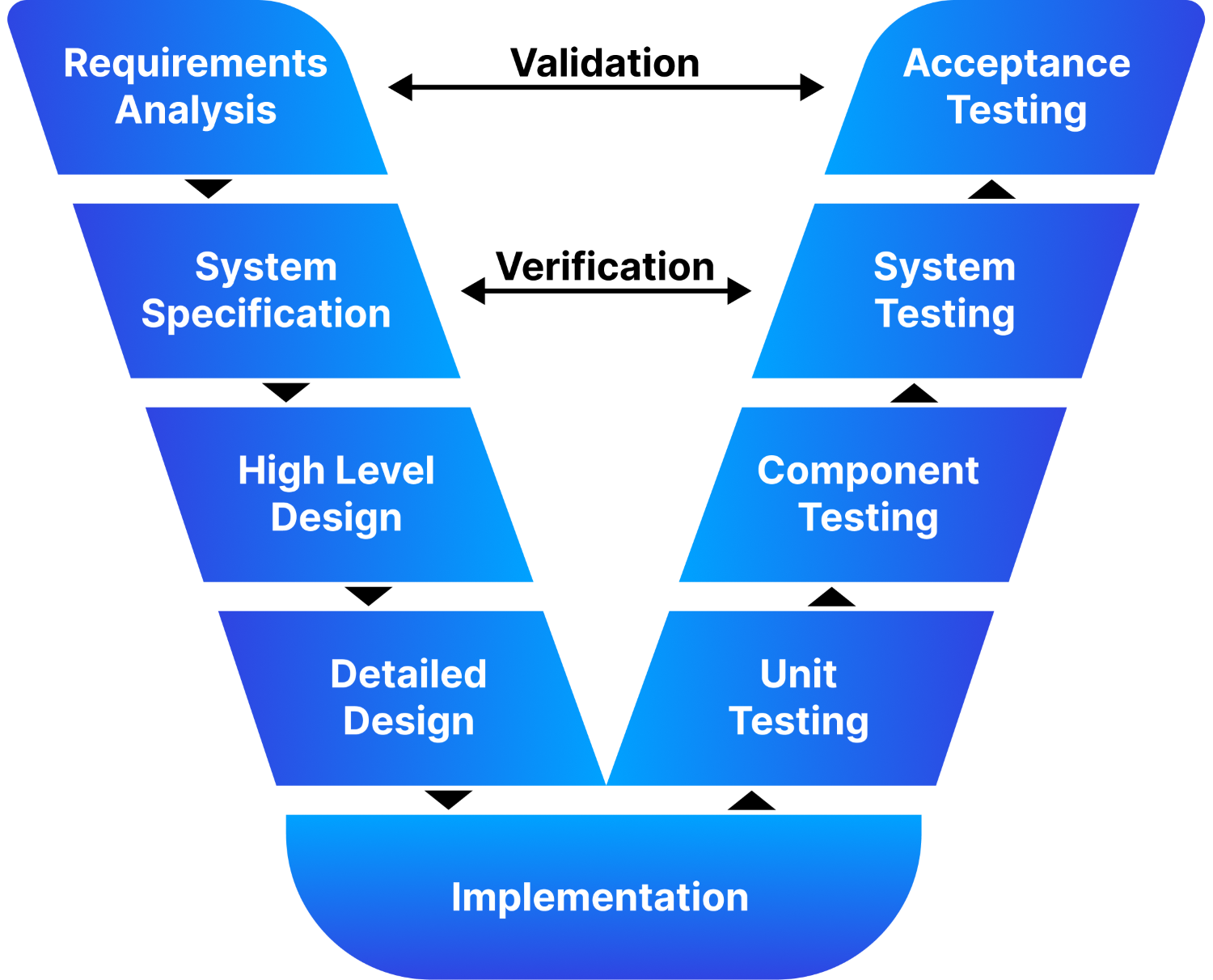

Our validation ensures your system is audit-ready for regulatory bodies such as USFDA, EMA, WHO, and MHRA.

Our validation ensures your system is audit-ready for regulatory bodies such as USFDA, EMA, WHO, and MHRA.

Our AMC services include routine calibration, chemical sanitization, hot water sanitization, instrument verification, and replacement of critical spares. This ensures minimum downtime, extended system life, and compliance sustainability.

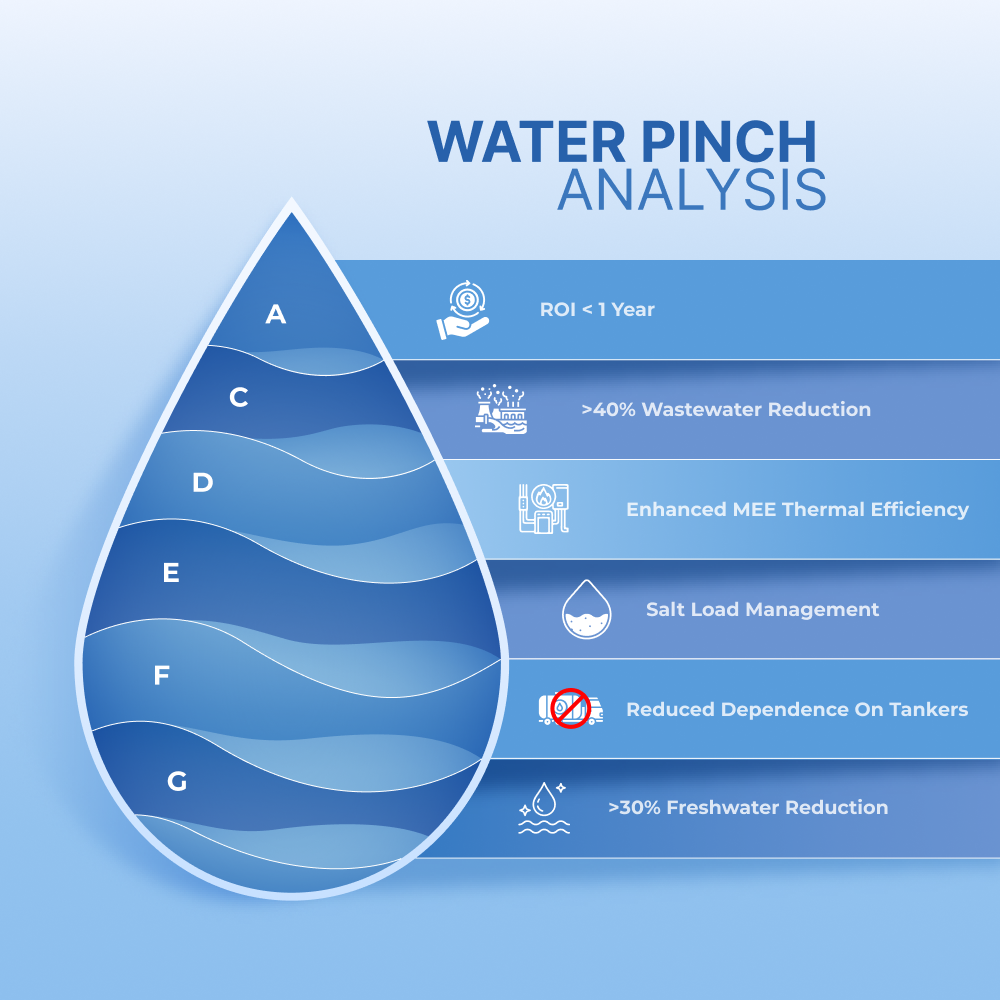

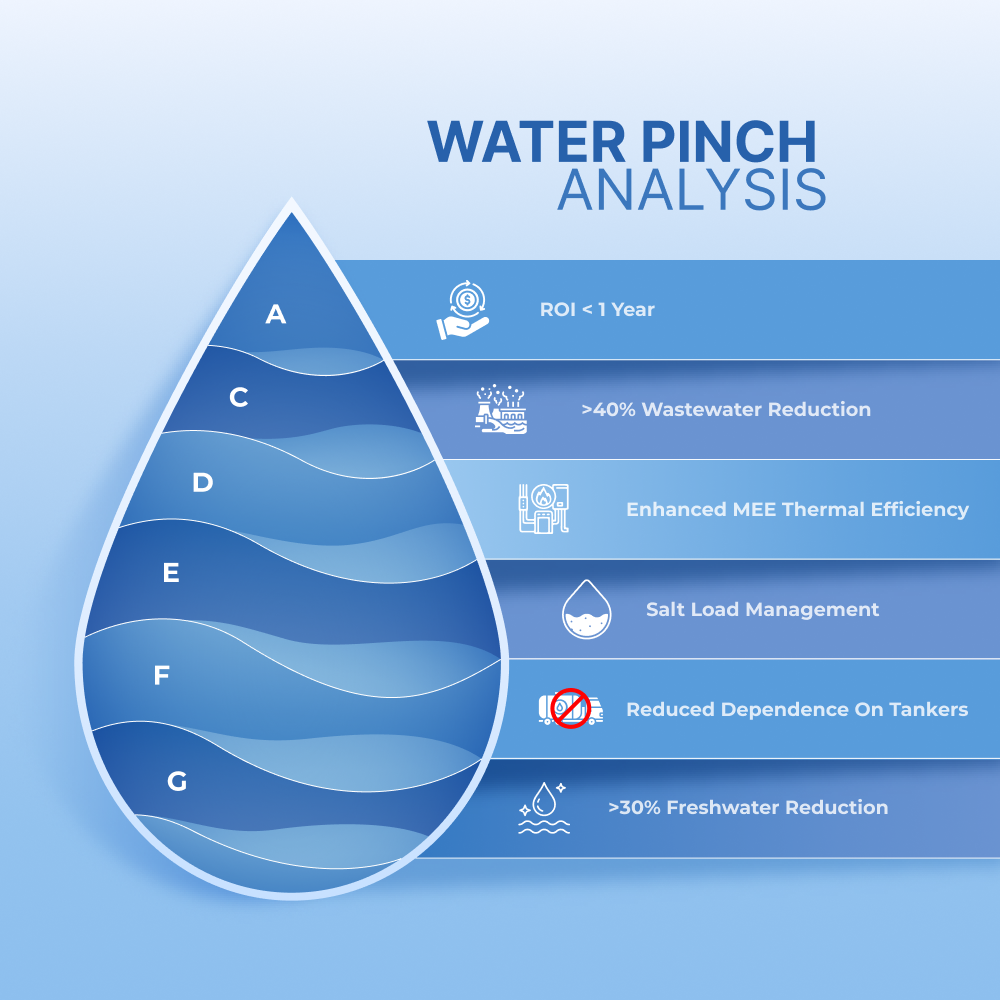

Water systems are high consumers of energy and resources, and we help clients achieve significant savings without compromising compliance.

These measures deliver long-term operational savings while supporting sustainability goals in pharma and FMCG industries.

Water systems are high consumers of energy and resources, and we help clients achieve significant savings without compromising compliance.

These measures deliver long-term operational savings while supporting sustainability goals in pharma and FMCG industries.