In highly regulated industries such as pharmaceuticals, biotechnology, chemicals, and FMCG, projects demand more than just equipment supply — they require end-to-end execution with compliance, efficiency, and sustainability built in.

At SVU Enterprises, we deliver Turnkey Engineering Projects and Design Consultancy services that take your requirements from concept to commissioning and qualification, ensuring that every project is technically sound, cost-effective, and audit-ready.

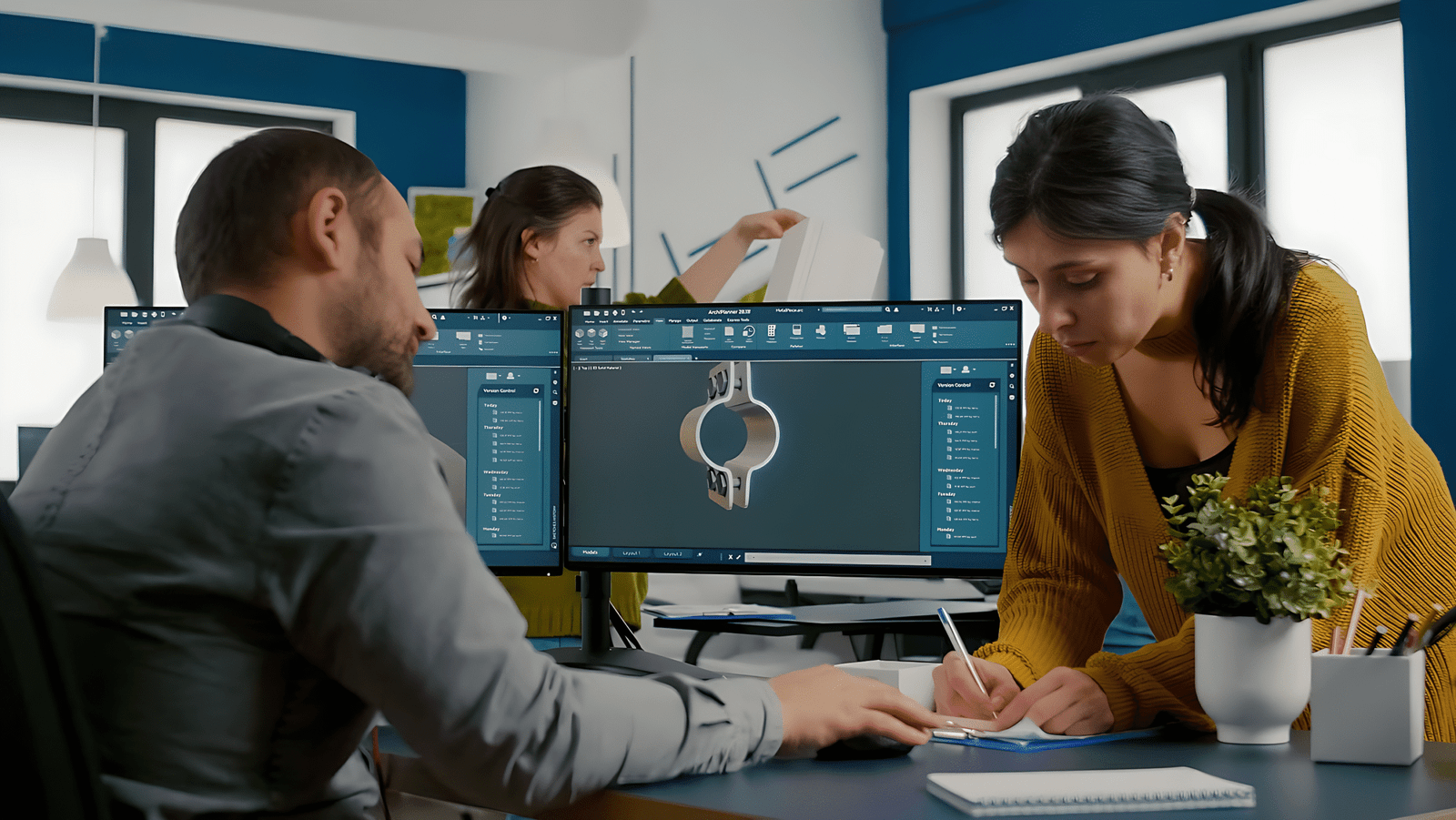

A strong project begins with the right design foundation. Our engineering team develops:

This ensures your design is technically robust, GMP-compliant, and practical for long-term operations.

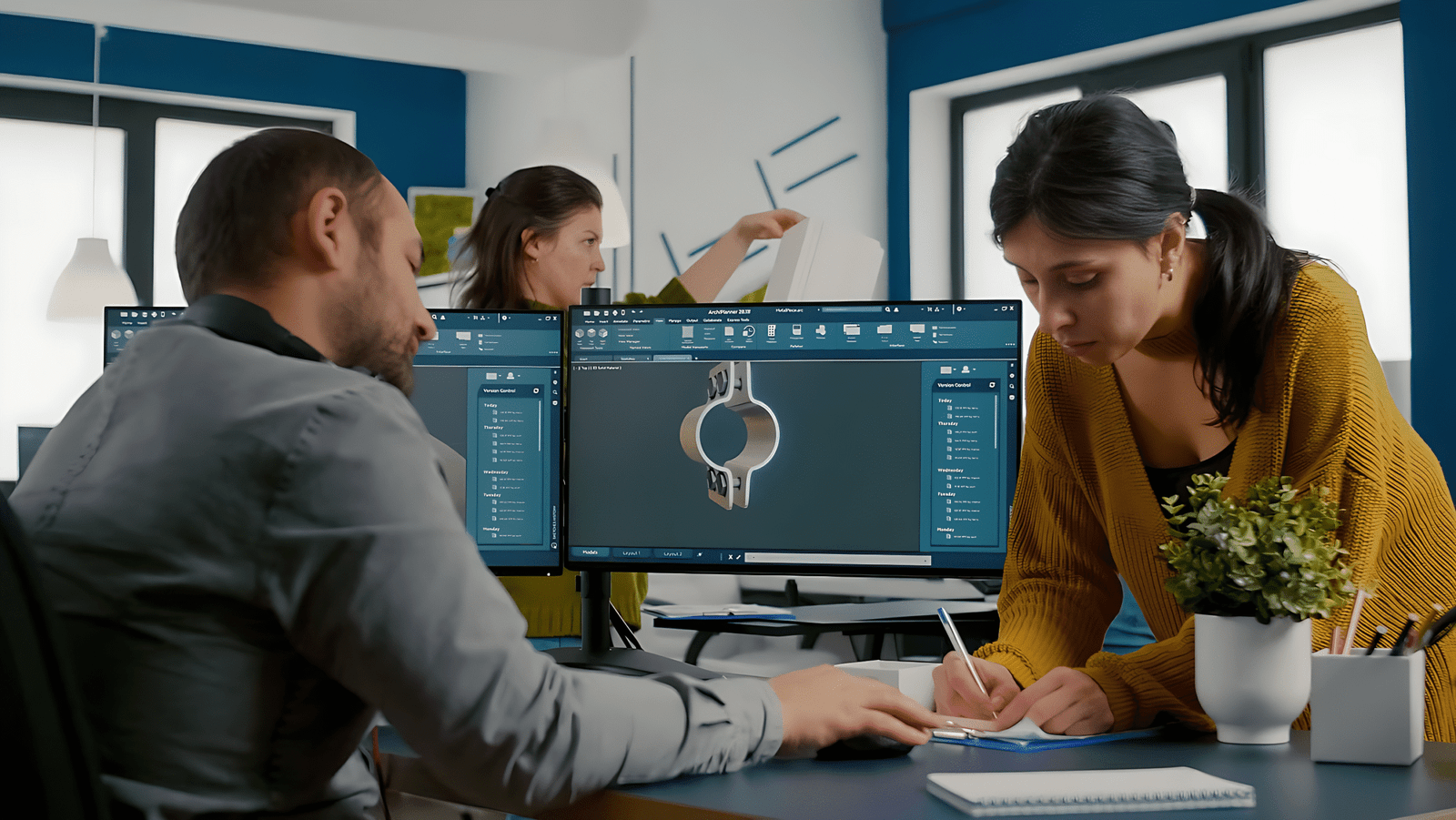

We handle projects across the entire lifecycle, ensuring seamless execution at every stage:

With SVU Enterprises, clients get a single partner for design, installation, automation, and validation — ensuring faster timelines and reduced risks.

We handle projects across the entire lifecycle, ensuring seamless execution at every stage:

With SVU Enterprises, clients get a single partner for design, installation, automation, and validation — ensuring faster timelines and reduced risks.

Utilities are the backbone of manufacturing facilities. Our consultancy covers:

We ensure that every utility and process system is designed for efficiency, reliability, and compliance.

Beyond compliance, we help clients achieve sustainability and operational cost savings through:

These studies deliver tangible savings in utilities and operations while supporting clients’ green and sustainable manufacturing goals

Beyond compliance, we help clients achieve sustainability and operational cost savings through:

These studies deliver tangible savings in utilities and operations while supporting clients’ green and sustainable manufacturing goals